Shunlitongda Electronics Technology (Dongguan) Co., Ltd.

+86 13826913652

+86 13826913652

slthardware@outlook.com

slthardware@outlook.com

Discussion on the Technology and Application of Injection Molding Hardware Products

plastic-metal injection molding products (also known as insert molding or metal-plastic hybrid parts):

1. Technological & Process Innovations

Popularity of Insert Molding:

Metal parts (e.g., screws, bearings, inserts) are molded directly into plastic, reducing assembly steps and improving structural strength and precision (common in automotive and electronics).

Micro-Molding with Precision Metal Parts:

Tiny metal components (e.g., SIM card trays, micro connectors) combined with high-precision plastic, demanding advanced molds and machines.

Multi-Material Molding:

Combining metals with engineering plastics (e.g., PA, PPS) for strength and lightweighting (e.g., car door handles, gearbox components).

2. Material Science & Performance Optimization

Metal-Plastic Interface Bonding:

Surface treatments (plating, laser etching, chemical coatings) to enhance adhesion and prevent delamination.

-High-Performance Plastics:

PEEK + metal inserts for high-temperature applications (aerospace), or conductive plastics + EMI shielding for electronics.

Eco-Friendly Materials:

Recyclable metals + bio-based plastics to meet circular economy demands.

3. Industry Applications & Market Trends

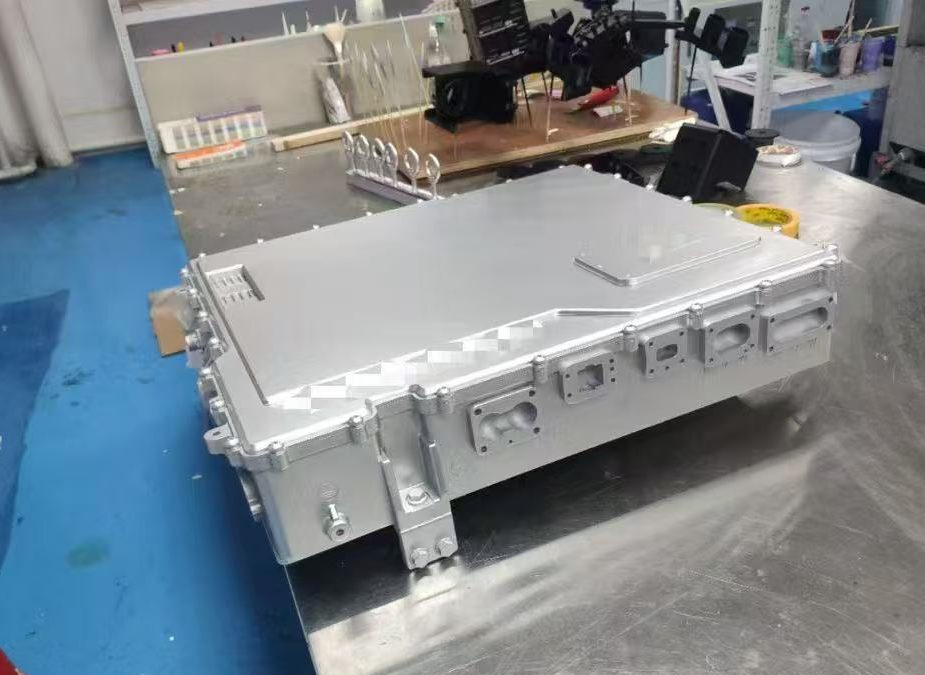

Automotive Lightweighting:

Hybrid metal-plastic structures (e.g., dashboard frames, battery housings) reduce weight while maintaining strength.

Consumer Electronics Integration:

Metal frames + plastic antenna designs (smartphones), waterproof structures in wearables.

Home Appliance Upgrades:

Seamless molding of metal hinges with plastic doors (refrigerators, washing machines) for durability and aesthetics.

4. Cost & Efficiency Challenges

Mold Complexity:

High-precision metal insert positioning requires error-proof molds, increasing upfront costs.

Automation Barriers:

Manual insert placement may limit efficiency; robotic or vision-guided systems are needed.

Yield Rate Issues:

Differential shrinkage (metal vs. plastic) causes warpage; solved via simulation (e.g., Moldflow) and process optimization.

5. Sustainability & Future Trends

Design for Disassembly:

Easier recycling (metal/plastic separation) to comply with regulations like WEEE.

3D-Printed Metal Inserts + Molding:

Enables low-volume customization (e.g., medical implant casings).

Smart Hybrid Products:

Metal sensors embedded in plastic (e.g., smart valves) for functional integration.

6. Common Problems & Solutions

Stress Cracking: Rounded edges or glass-fiber reinforcement at metal-plastic joints.

Corrosion Risk: Use stainless steel or passivated metal inserts.

Thermal Expansion Mismatch: Material selection or structural design to accommodate expansion.