Shunlitongda Electronics Technology (Dongguan) Co., Ltd.

+86 13826913652

+86 13826913652

slthardware@outlook.com

slthardware@outlook.com

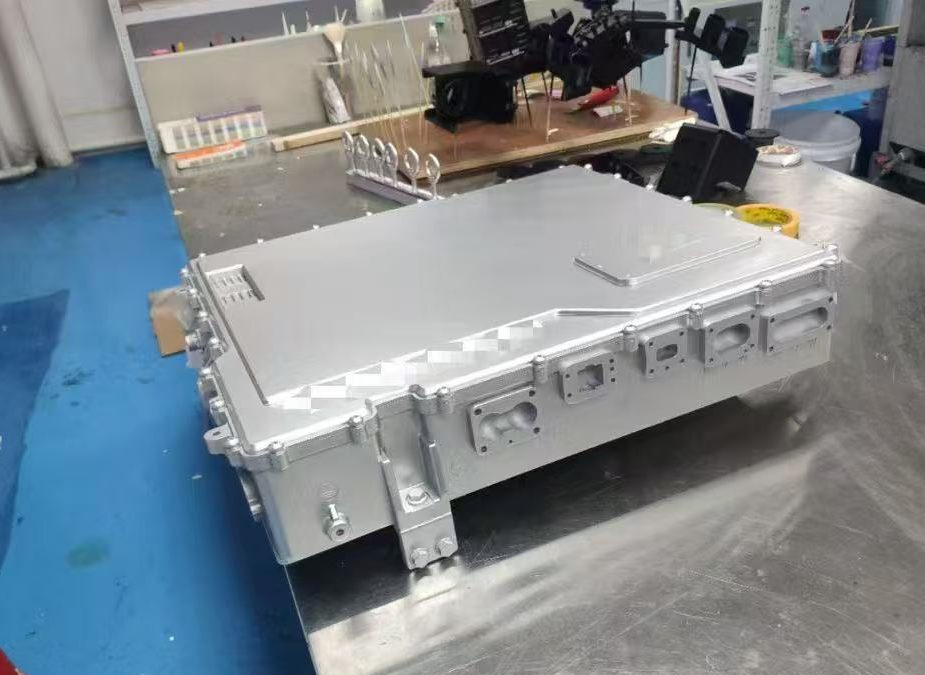

Car navigation frame

1. Introduction

The automotive navigation bezel is a critical component that houses and protects the infotainment display in modern vehicles. It enhances aesthetics, provides structural support, and ensures user-friendly interaction. Below is a detailed production process along with its key applications.

2. Production Process

2.1 Material Selection

Primary Materials:

Plastics: ABS, PC (Polycarbonate), or PC/ABS blends (for durability and lightweight properties).

Metals: Aluminum or magnesium alloy (for premium finishes and rigidity).

Coatings: UV-resistant paint, electroplating, or soft-touch finishes for enhanced aesthetics.

2.2 Manufacturing Steps

Injection Molding (Plastic Bezels)

Granules are melted and injected into precision molds.

High-pressure molding ensures dimensional accuracy.

Cooling and ejection follow molding.

CNC Machining (Metal Bezels)

Aluminum/magnesium blocks are milled into precise shapes.

Surface polishing and deburring ensure smooth edges.

Surface Treatment

Painting/Electroplating: Adds corrosion resistance and premium look.

Laser Engraving: For branding or decorative patterns.

Texturing: Soft-touch or matte finishes for better grip.

Assembly & Integration

Mounting clips/screws are installed.

Integration with touch sensors (if applicable).

Quality checks for fitment and finish.

Final Inspection & Packaging

Dimensional accuracy, scratch resistance, and functionality tests.

Anti-static packaging to prevent transit damage.

3. Key Applications

Protection & Structural Support: Shields the display from dust, vibrations, and impacts.

Aesthetic Enhancement: Complements the car’s interior design with glossy/matte finishes.

User Interaction: Some bezels integrate touch controls or backlit buttons.

Brand Differentiation: Custom designs reflect OEM branding (e.g., luxury vs. sporty styles).

4. Quality Standards

Durability: Resists UV rays, heat (up to 85°C), and chemical exposure (cleaning agents).

Precision: Tight tolerances (±0.1mm) for seamless dashboard integration.

Safety: No sharp edges; compliant with automotive regulations (e.g., ISO/TS 16949).

5. Conclusion

The navigation bezel combines engineering precision and design excellence to enhance both functionality and vehicle aesthetics. Advanced materials and coatings ensure longevity, while flexible manufacturing accommodates diverse automotive styles.

- ← Previous Car Navigation and Navigation Frame

- → Next No more